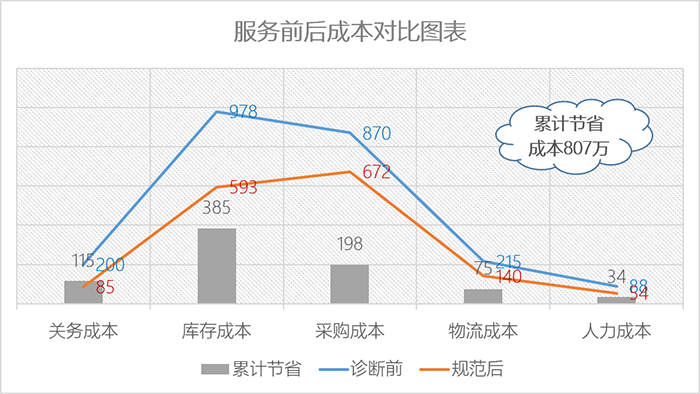

18062701# Supply chain management customized service case

Customer case

Service cycle: June 27, 2018-July 31, 2019 Service team: Guangdong Donghua Supply Chain Technology Co., Ltd. Supply Chain Leading Expert: Chief Consultant of Supply Chain Center-Jin Pengyuan Cooperation Type: Customized Supply Chain Managem...